Introduction

A failed surge protection device can leave your electrical system exposed. Ignore it, and costly downtime follows. The good news: with just a multimeter, you can quickly assess your SPD’s health and prevent disaster.

The Warning Signs of SPD Failure: Symptoms and Root Causes

When an SPD breaks, your system loses its protection against harmful surges without you knowing it. The first step in stopping big breakdowns is to notice early warning indicators and figure out why they happen.

Quick Diagnosis: 3 Signs That Your SPD Has Failed

- The indicator light is off or red. Many SPDs offer a status window. A dark or red light usually signifies that something has gone wrong.

- Frequent damage to equipment: If gadgets downstream stop working following storms or voltage surges, the SPD may already be dead.

- Heat or a burning smell: SPD parts that are overloaded can get hot or even burn, which means there is damage within.

Why do SPDs “burn out”? Explaining Core Failure Mechanisms

- Repeated surge exposure: SPD parts wear out when lightning strikes or grid problems happen all the time.

- MOV degradation: Metal Oxide Varistors stop working after taking in too many surges.

- Harsh environments: Too much heat, humidity, or dust speeds up internal failure.

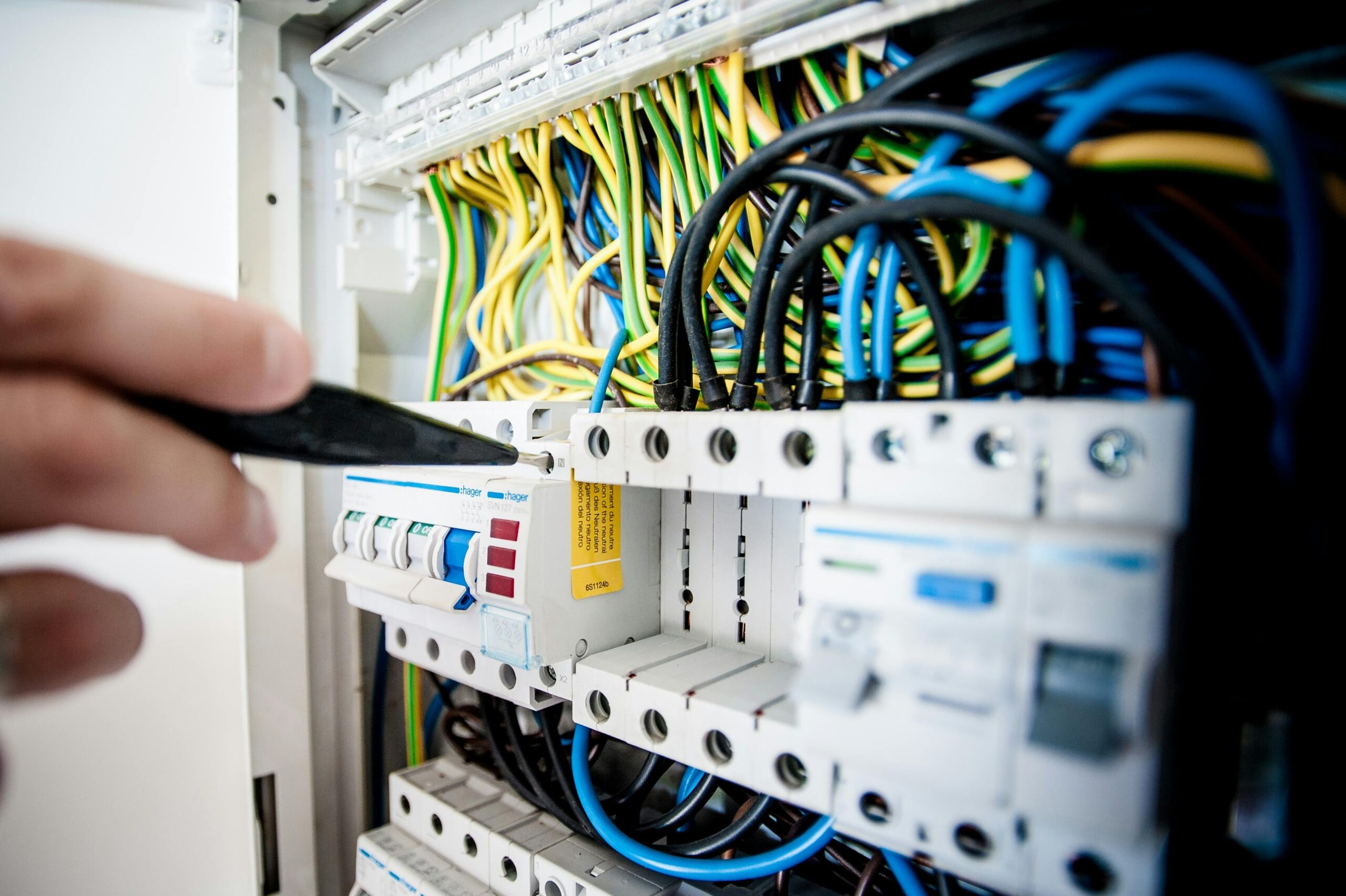

How to use a multimeter: step-by-step SPD testing and safety rules

Without the right safety measures, testing an SPD could be dangerous and inaccurate. Following the right steps will keep you safe and provide you trustworthy outcomes.

Basic Safety Rule: Turn Off Power Before Testing

- Completely cut off power: Turn off the main supply to avoid getting shocked or damaging the equipment.

- Discharge residual voltage: Use an insulated instrument to short-circuit the SPD terminals and let the stored energy out.

- Wear safety gear: Insulated gloves and safety glasses lower the dangers during testing.

Testing with a multimeter: MOV, diode, and resistance modes

- Resistance mode: Measure the distance between the MOV terminals. A normal SPD has a high resistance, which is more than 1MΩ. A short circuit happens when the resistance is close to 0Ω.

- Diode mode: For SPDs with diodes, the values for forward and reverse should be different. The device is broken if both conduct or neither does.

- Check for capacitance and continuity: Some SPDs need more checks to make sure there are no hidden short circuits.

Testing for Continuity in Signal-Line SPDs

- Set your multimeter to continuity mode.

- Check the SPD terminals for a signal. A persistent open circuit means that a fuse or part has broken.

- A healthy SPD should have minimal resistance or be able to hear continuity, which shows that the circuit is protected.

Decoding Test Results: Maintenance, Replacement, and Long-Term Strategies

Testing only tells half the story. Proper interpretation ensures the right maintenance action, whether that’s continued use or immediate replacement.

Diagnostic Reference Table: What Test Results Really Mean

| Test Result | Meaning | Maintenance Action |

|---|---|---|

| Open circuit | Blown fuse or MOV damage | Replace SPD immediately |

| Short circuit | MOV fully broken down | Replace at once to avoid accidents |

| Low resistance but not short | Degraded SPD with reduced capacity | Preventive replacement recommended |

| High resistance (normal) | SPD is healthy | Continue using, schedule periodic checks |

How to make SPD last longer: from regular checks to controlling the environment

- Scheduled testing: Use a multimeter to check every 6 to 12 months to find problems early.

- To slow down wear, keep the panels dry, clean, and well-ventilated.

- Choose SPDs with the right surge capacity and reaction time for your network.

- Layered defense: For the best protection, put SPDs at the main distribution, branch, and terminal levels.

Conclusion

Even though your SPD is little, it protects your whole electrical system. You may avoid expensive breakdowns by regularly testing your multimeter and taking care of it. Check your SPD today so you don’t have to wait for it to break down.