TLDR

A Direct-On-Line starter applies full line voltage to a motor instantly. It’s simple, low cost, and reliable for small motors. The risk is not the motor itself but the upstream system. If transformer capacity is too small, voltage dip exceeds 10 percent, or the load demands sustained low-speed torque, DOL should be ruled out immediately.

How a Direct-On-Line Starter Applies Full Voltage at Startup

A Direct-On-Line starter connects an electric motor directly to the power supply.

When the start button is pressed, the contactor closes and full line voltage is applied to the motor terminals. There is no voltage reduction and no ramping period.

DOL starting is typically used on small to medium induction motors, most often up to 7.5 kW or 10 HP. This limit is not arbitrary. It reflects how much electrical and mechanical stress the surrounding system can absorb during startup.

DOL works when the system is stiff. It fails when the system margin is thin.

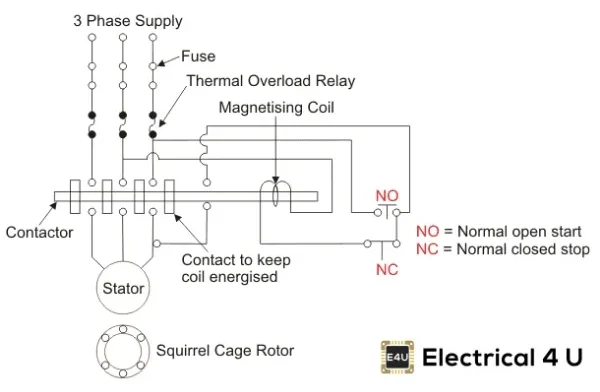

Key Components That Control and Protect a DOL Starter

| Component | Role in the System |

|---|---|

| Contactor | Connects and disconnects the motor. Subject to high inrush current and contact erosion. |

| Overload relay | Protects against thermal overload, not short circuits or voltage dip. |

| Control panel | Houses start stop controls and indicators. Often affected first by voltage dips. |

| Wiring and enclosure | Line impedance here directly affects startup voltage drop and relay behavior. |

From field experience, most DOL failures are not caused by the starter itself. They are triggered by how these components interact with the upstream supply.

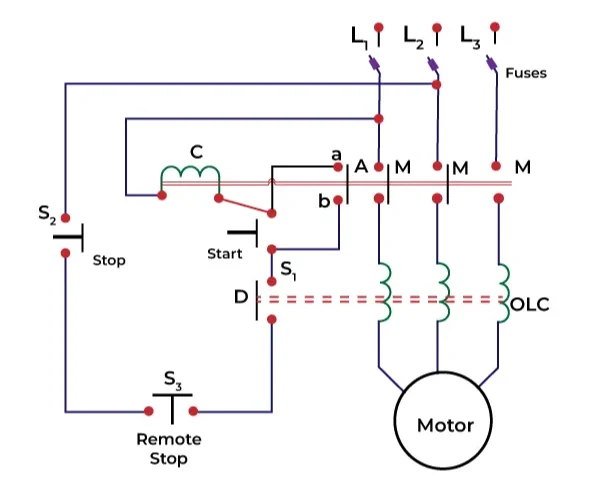

Common DOL Starter Configurations and When They’re Used

| Configuration | Key traits | Where it works |

|---|---|---|

| Basic DOL | Minimal protection and control | Stable supply, infrequent starts |

| Automated DOL | Timers and status feedback | Basic sequencing and monitoring |

| Remote-control DOL | Off-site start stop control | Hazardous or inaccessible locations |

| Three-phase DOL | High starting torque | Industrial motors above 1.5 kW |

| Single-phase DOL | Compact and simple | Light-duty loads up to 3 kW |

The configuration choice does not reduce inrush current. It only changes how the system is supervised.

Why DOL Starters Are Still Used in Real Systems

DOL starters remain widely used because their behavior is direct and predictable.

They offer simple electrical logic, low upfront cost, fast acceleration to rated speed, and compact panel layouts. In stable industrial networks, they are easy to commission and easy to troubleshoot.

Where the supply is strong, DOL remains one of the most transparent motor starting methods available.

Where DOL Starters Create Electrical and Mechanical Stress

This is where DOL decisions are often made incorrectly.

Starting current typically reaches six to eight times full-load current. If voltage dip exceeds 10 percent, PLC resets, lighting flicker, and nuisance trips are common.

Mechanical shock is transferred directly to shafts, couplings, and driven equipment. Contactor wear accelerates when inrush current approaches or exceeds design margins.

There is also no inherent protection against supply instability.

Clear stop conditions

If transformer capacity is less than five times the motor’s starting kVA, DOL risk rises sharply.

If measured voltage dip exceeds 10 percent, DOL should be rejected.

If the load requires sustained torque below 80 percent speed, DOL is not the problem, but star-delta is also likely to fail.

These thresholds come from repeated field failures, not theory.

Applications Where DOL Starting Works Without Causing Problems

| Industry | Typical equipment |

|---|---|

| Manufacturing | Light conveyors, mixers |

| Water treatment | Small centrifugal pumps |

| Agriculture | Irrigation pumps |

| Construction | Portable generators |

| HVAC | Fans and air handlers |

| Mining and oil and gas | Auxiliary pumps |

Across these applications, the deciding factors are load inertia and supply stiffness, not industry category.

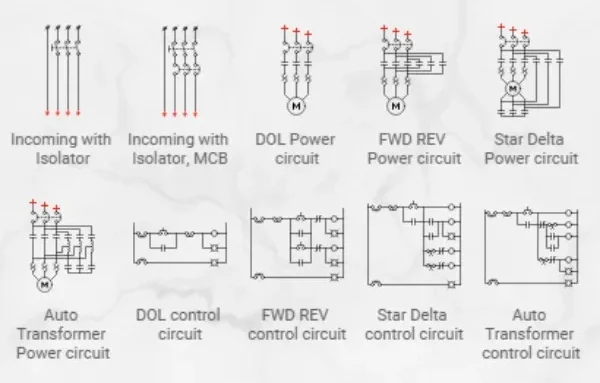

How DOL Starting Compares to Star-Delta Soft Starters and VFDs

| Condition | DOL | Star-delta | Soft starter | VFD |

|---|---|---|---|---|

| Starting current | Very high | Reduced | Adjustable | Low |

| Voltage dip control | None | Limited | Moderate | Strong |

| Low-speed torque | High shock | Weak | Controlled | Full control |

| System impact | Severe on weak grids | Moderate | Low | Lowest |

| When to reject | Voltage dip above 10 percent | Constant load torque | Network sensitive | Harmonics limited |

If voltage dip exceeds 10 percent, stop DOL.

If transformer margin is below five times starting kVA, stop DOL.

If load torque is flat at low speed, skip star-delta entirely.

This comparison should end debate early.

How to Decide If DOL Is the Right Starting Method

Confirm motor size is within the practical DOL range.

Calculate transformer margin, not just motor power.

Measure or estimate voltage dip instead of guessing.

Review the actual load torque curve.

Check contactor rating beyond motor full-load current.

Assess start frequency, not average runtime.

At Soltree, most DOL misapplications we encounter fail at the system boundary, not at the motor or starter itself.

FAQ

What is the maximum motor size for a DOL starter

In most systems, DOL starting is best limited to motors up to 7.5 kW or 10 HP. Above this range, startup current often causes unacceptable voltage dip unless transformer capacity, short-circuit level, and supply stiffness are verified and proven stable under real load conditions.

Can a DOL starter control motor speed

No. A DOL starter applies full line voltage instantly and provides start and stop control only. It does not regulate speed, torque ramp, or acceleration. Any application requiring speed adjustment or controlled startup must use a soft starter or a variable frequency drive.

What protection does a DOL starter provide

A standard DOL starter provides thermal overload protection only. It does not protect against short circuits, voltage dips, or supply instability. Those protections must be handled upstream through circuit breakers, fuses, or dedicated voltage protection devices.

Is DOL suitable for frequent starting

DOL can handle occasional starts, but frequent starting significantly increases thermal stress and accelerates contactor wear. If starts exceed typical duty cycles or occur under load, soft starters are preferred to reduce electrical shock and extend component life.

Single-phase or three-phase DOL starter

Single-phase DOL starters are suited for light-duty equipment up to 3 kW. Three-phase DOL starters are used for industrial motors above 1.5 kW, where balanced current, higher torque, and better efficiency are required.

What installation checks matter most for DOL starters

Measure actual voltage dip during startup, verify grounding integrity, confirm overload relay settings, and inspect contactor condition. Many DOL failures occur not at the motor, but due to weak supply margins or incorrect protection coordination.

When DOL Starting Makes Sense and When It Doesn’t

DOL motor starters remain effective where supply strength and load behavior are predictable. They are not obsolete. They are simply unforgiving.

When transformer margin is thin, voltage stability matters, or load torque is continuous at low speed, DOL should be excluded early. In those cases, star-delta, soft starters, or VFDs are not upgrades. They are corrections.

That distinction is what prevents repeat failures and unnecessary redesigns.