TLDR

Push button switches provide deliberate control, predictable behavior, and mechanical reliability when the application demands clear on-off actions. Their value depends on load type, control logic, and environment. Used in the right conditions, they outperform toggles, selectors, and touch interfaces in both safety and long-term stability.

What a Push Button Switch Does and Why It’s Still Widely Used

A push button switch is an electromechanical control device that connects or disconnects a circuit through direct physical actuation. One press triggers a defined action. Release or a second press determines the next state.

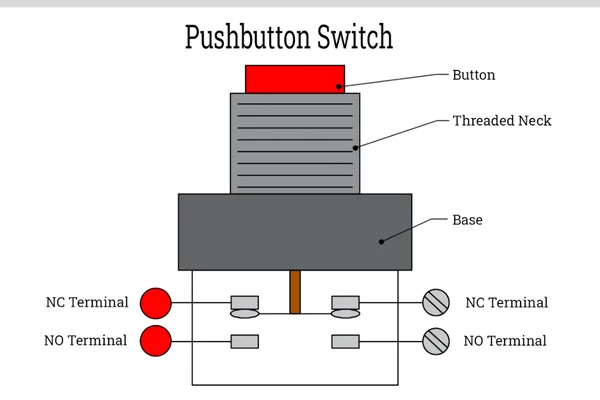

Typical construction includes a button cap, a return spring, moving and fixed contacts, and electrical terminals.

Housings range from plastic to metal. Shapes include round, square, flat, and ergonomic profiles. Color coding supports fast visual recognition in control panels.

Push buttons remain common because they create intentional control with physical feedback.

How Push Button Switches Create Reliable On-Off Control

Push button switches rely on spring-driven contact movement, but the behavioral outcome matters more than the mechanism itself.

Pressing the button compresses the spring, shifts the moving contact, and changes the circuit state immediately. Releasing the button returns the spring to rest and separates or reconnects contacts depending on design.

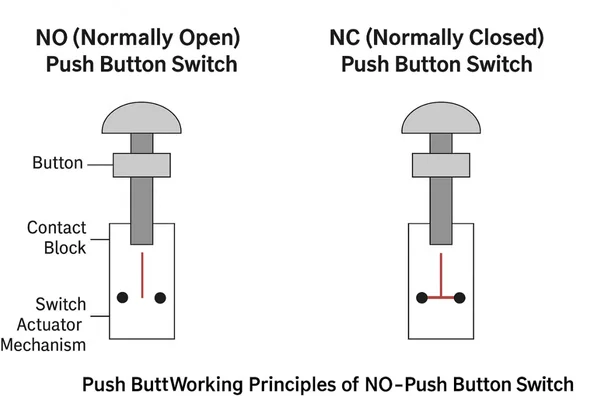

Normally open designs keep the circuit off by default and energize only during actuation. This reduces unintended startup and is widely used for start commands.

Normally closed designs keep the circuit energized until pressed. This fail-safe behavior explains why safety circuits and emergency stops rely on NC contacts. A broken wire forces shutdown instead of silent operation.

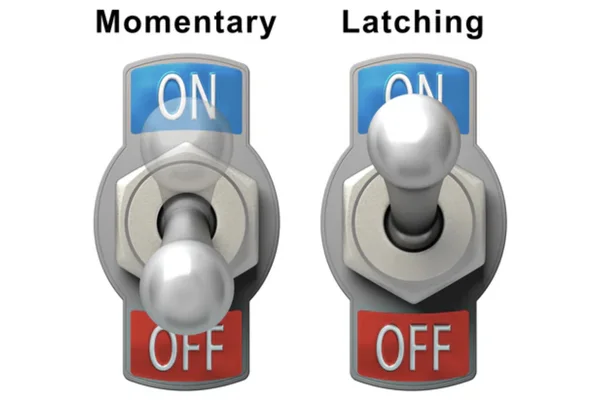

Momentary action holds the state only while pressed. This provides tighter control logic and limits runaway conditions in automation systems. Latching action toggles and holds the state, which works well for simple power functions but tolerates less logic error.

DC circuits require special attention. DC does not self-extinguish arcs, so contact wear increases significantly at the same voltage. Underrated DC use shortens service life through pitting and welding.

The Most Common Push Button Types and When Each One Makes Sense

Momentary push buttons work best for commands, jog functions, and safety-related inputs that must stop when released.

Latching push buttons suit basic on-off control where logic is simple and operating states are clear.

Normally open and normally closed variants serve different safety and control priorities. Miniature and PCB-mounted buttons support resets and input keys. Panel-mounted buttons suit control enclosures.

Waterproof and dustproof designs with higher IP ratings handle washdown and outdoor exposure. Explosion-proof buttons protect hazardous locations. Emergency stop buttons use large red mushroom heads with NC contacts for rapid shutdown. Illuminated buttons provide status visibility. Industrial square buttons resist mechanical abuse.

Type selection should always follow function first, not appearance.

Why Push Button Switches Are Chosen Over Other Controls

Push button switches are not universally better. They are better under specific conditions.

Compared with toggle switches, push buttons reduce accidental activation, provide clearer tactile feedback, and tolerate high-cycle use more effectively. Toggles wear faster and are rarely used in safety circuits.

Compared with selector switches, push buttons excel at single defined actions. Selectors make more sense when multiple modes must be maintained.

Compared with touchscreens, push buttons remain reliable with gloves, dirty hands, or moisture present. They offer immediate response in emergency situations and predictable behavior during power loss.

Durability only holds when current stays within rated limits, DC loads are properly derated, and contact material matches the load type. Many failures originate when these conditions are ignored.

Where Push Button Switches Perform Best in Real Use

Consumer electronics rely on momentary buttons for fast and repeatable input. Household appliances use push buttons to ensure clear user intent for power and function selection.

Industrial systems depend on push buttons for start-stop stations, emergency shutdown circuits, and operator panels where response time and certainty matter.

Public and safety equipment such as doorbells, alarms, and fire activation devices require immediate, unambiguous action. Automotive and transportation systems favor tactile confirmation for auxiliary controls.

Harsh environments including outdoor, marine, and medical settings benefit from sealed designs and mechanical certainty.

How to Choose the Right Push Button Switch for Your Application

Start by defining behavior. Decide whether the function requires normally open or normally closed contacts and whether action should be momentary or latching.

Match voltage and current ratings to real operating conditions. Most failures come from underestimating load type, not voltage rating. Inductive and DC loads require higher margins.

Evaluate the environment and select IP protection based on dust, moisture, cleaning, and chemical exposure. Confirm ergonomics such as button size, actuation force, and visibility.

Choose the correct mounting method and verify required certifications such as CE or UL for regulated systems.

Manufacturers like Soltree design low-voltage push button solutions around these constraints to reduce field failures rather than just meeting nominal ratings.

Common Push Button Failures and How to Prevent Them

Typical failures include contact oxidation or pitting, spring fatigue that prevents return, and indicator LED burnout.

Repair makes sense for loose wiring, surface contamination, or minor contact resistance increases. Replacement is smarter when repeated contact welding, severe pitting, or DC arc damage appears.

Many perceived quality issues trace back to incorrect selection rather than manufacturing defects. Keeping surfaces clean, avoiding overload, and using sealed designs in harsh environments extend service life.

FAQ

What is the difference between a normally open and normally closed push button?

A normally open push button keeps the circuit open until pressed, allowing current to flow only during actuation. A normally closed button does the opposite and interrupts current when pressed. NC designs are preferred in safety circuits because wiring faults force a shutdown instead of leaving equipment energized.

When should I use a momentary push button instead of a latching one?

Use a momentary push button when the action should occur only while the button is pressed, such as jogging, reset commands, or safety-related inputs. Momentary designs reduce runaway conditions and provide tighter control logic. Latching buttons are better suited for simple on-off power functions.

Are push button switches suitable for DC circuits?

Yes, but DC applications require more caution. DC does not self-extinguish electrical arcs like AC does, which increases contact wear. Push buttons used in DC circuits must be properly rated and often derated to prevent contact pitting, welding, and reduced service life.

Why are emergency stop buttons normally closed?

Emergency stop buttons use normally closed contacts so that any wiring failure, broken conductor, or loose terminal triggers a shutdown. This fail-safe behavior ensures the machine stops even if the control circuit is damaged, which is critical for personnel safety and compliance with industrial safety standards.

What causes push button switches to fail most often?

Most failures come from incorrect selection rather than poor manufacturing. Underrated contact capacity, ignoring inductive or DC loads, and insufficient environmental protection lead to contact damage and spring fatigue. Mechanical wear usually appears only after electrical stress exceeds the switch’s design limits.

How long do push button switches typically last?

Mechanical life commonly ranges from 100,000 to over 1 million operations, depending on design and materials. Electrical life is usually lower and depends heavily on load type and switching frequency. Inductive and DC loads significantly shorten service life if not properly accounted for during selection.

When should a push button switch be replaced instead of repaired?

Replacement is recommended when contacts show repeated welding, severe pitting, or arc damage, especially in DC applications. These issues indicate selection or load mismatches. Cleaning or minor repairs only make sense for contamination or loose wiring, not for structural or contact degradation.

Do push button switches need regular maintenance?

Most push button switches are low-maintenance, but periodic inspection helps prevent downtime. Keep surfaces clean, check terminals for looseness, and ensure operating current stays within rated limits. In dusty or wet environments, sealed designs reduce maintenance frequency and extend service life.