TLDR

This guide explains electric wires and cables by voltage, insulation, structure, and application. It adds clear decision logic and numeric thresholds so you can choose correctly, avoid common failures, and stay compliant in real installations.

Wire vs Cable – What Actually Changes in Real Installations

Wire

What it is One electrical conductor

Form Solid or stranded

Insulation Optional

Best for Short, fixed, low-risk internal connections

Cable

What it is Two or more insulated conductors under one sheath

Form Conductors plus jacket, sometimes shielding or armor

Best for Building wiring, equipment feeds, control and automation

Rule of thumb

Single function, short run → wire

Long run, protection needed, mixed power and control → cable

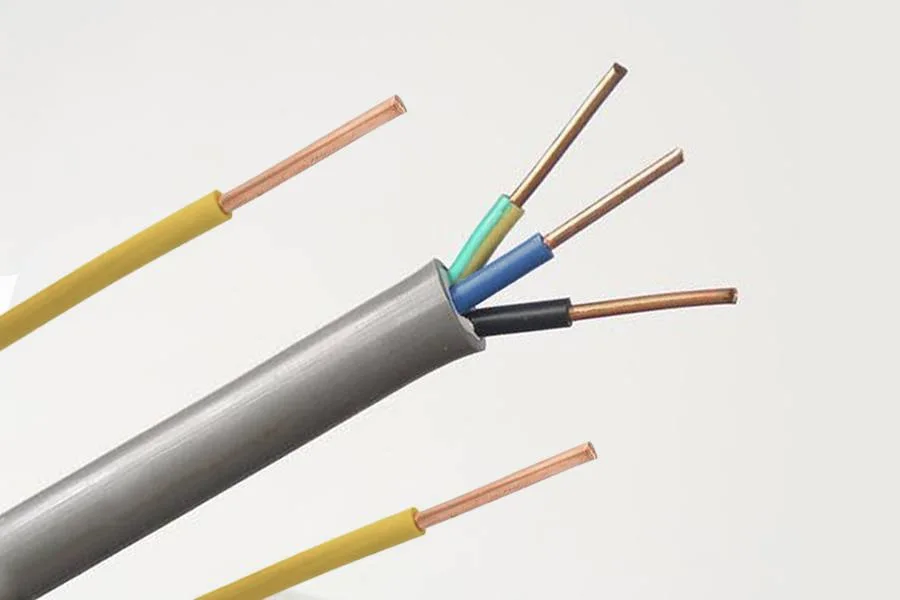

What’s Inside a Cable and Why Each Layer Matters

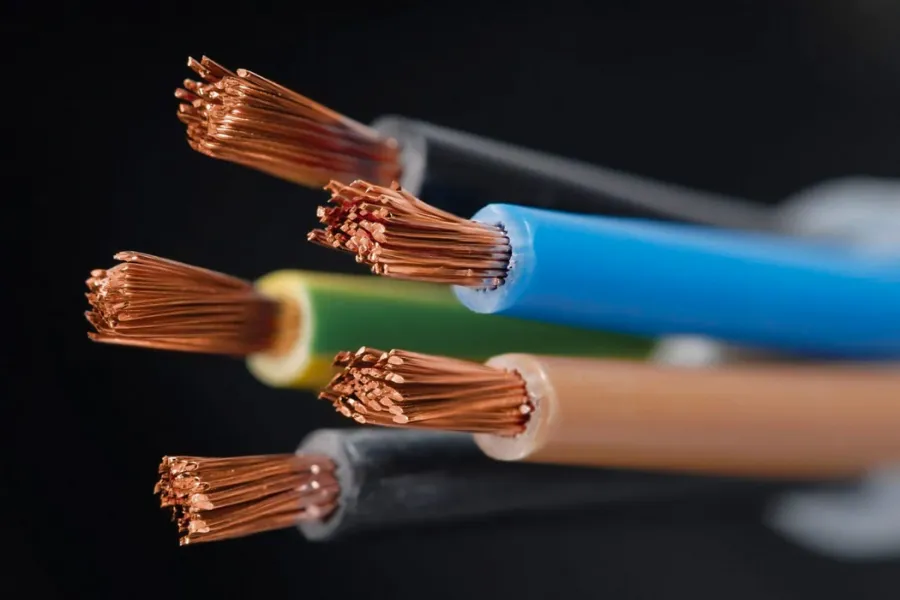

Conductor

Copper High conductivity and stable terminations

Aluminum About 60% of copper conductivity, lighter and lower cost, requires larger size

Form

Solid for permanent installs

Stranded for vibration or movement

Insulation

PVC General-purpose with lower temperature rating

XLPE Higher ampacity and better heat and chemical resistance

Rubber Extreme flexibility for cold or mobile use

Silicone Operates from -60°C to 200°C

Mineral insulation Fire-survivable with zero smoke

Shielding

Limits EMI and noise coupling

Required for instrumentation, VFD motor leads, and control signals

Armor

Protects against impact, compression, and rodents

Common for burial and industrial areas

Outer Jacket

Defends against UV, moisture, chemicals, and abrasion

Voltage Classes and Where Each One Is Used

| Voltage class | Range | Typical use |

|---|---|---|

| Low voltage | ≤1000 V | Homes, buildings, machinery |

| Medium voltage | 1–36 kV | Feeders, substations, large facilities |

| High voltage | >36 kV | Long-distance transmission |

Insulation Types and the Environments They’re Built For

Thermoplastic – THHN, THWN, PVC

Indoor branch circuits and conduit runs

XLPE – XHHW, MV XLPE

Outdoor, industrial, and medium-voltage systems

Rubber – W, DLO

Welders, cranes, and mobile equipment

Mineral-Insulated

Emergency circuits, tunnels, and fire zones

LSZH

Public buildings, data centers, and transit areas

Silicone

Ovens, furnaces, and extreme hot or cold locations

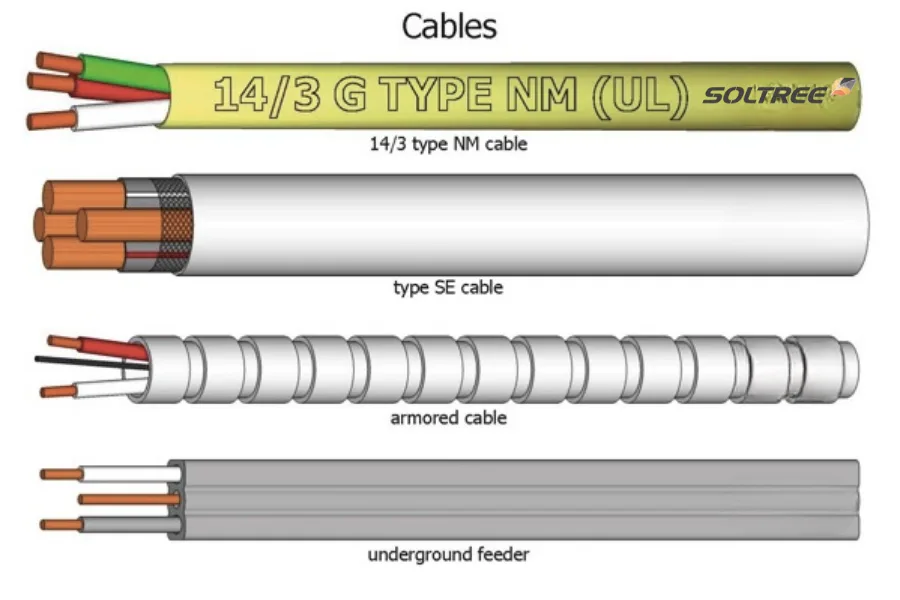

Common Cable Constructions and Where They Fail or Succeed

NM Cable

Dry residential walls only

Fails in damp or exposed locations

Armored Cables – AC, MC, SWA

AC for commercial interiors

MC for industrial and higher protection

SWA for burial and harsh environments

Control and Instrumentation Cables

Multi-core, shielded, and noise-resistant

Used for PLCs, sensors, and automation

Data Communication Cables

This section is included for routing and interference context, not power delivery selection

Coax for RF and legacy broadband

Twisted pair for Ethernet and telecom

Fiber for high-speed, EMI-immune links

Specialty Cables

PV cable UV-resistant and 90–105°C+, DC rated

Submersible Watertight and pressure-resistant

Welding High current and ultra-flexible

Flat cable Surface routing and retrofit work

How to Choose the Right Cable Without Guesswork

A fast decision table

| Installation environment | Voltage | Movement | Fire requirement | Recommended cable family |

|---|---|---|---|---|

| Dry interior wall | ≤600 V | No | Standard | NM or THHN in conduit |

| Industrial floor | ≤1000 V | No | Low smoke | MC or XLPE |

| Outdoor exposed | ≤1000 V | No | UV resistant | XHHW or XLPE |

| Mobile equipment | ≤600 V | Yes | Standard | Rubber insulated |

| Public building | ≤1000 V | No | Fire safety | LSZH or MI |

| Solar array | DC ≤1500 V | No | UV and heat | PV cable |

Practical Numeric Thresholds Engineers Actually Use

Voltage drop

Keep branch circuits under 3%

Keep combined feeder plus branch under 5%

Temperature derating

For many 90°C XLPE cables, expect 10–15% ampacity reduction for every 10°C above 30°C ambient

Long extension cords

Beyond 30 m, stepping up one wire gauge is often required to control voltage drop under load

These ranges reflect common NEC and IEC field practice.

FAQ

Which cable should be used for in-wall residential wiring?

For dry interior walls, NM-B cable is standard and code-compliant. In basements, garages, or commercial spaces, THHN in conduit or MC cable is often required. Moisture exposure, mechanical protection, and local electrical codes ultimately determine the correct wiring method.

What should I look for when choosing extension cords for a workshop?

Start with ampacity, not length. Most power tools require at least 14 AWG or 2.0 mm² conductors. For runs longer than 30 m, step up one wire gauge to limit voltage drop. Rubber-jacketed heavy-duty cords offer better durability.

Why shouldn’t power cables and data cables run together?

AC power cables generate electromagnetic fields that interfere with low-voltage data signals. Parallel routing can cause data loss and unstable communication. Maintain 20–30 cm separation, cross at 90 degrees when necessary, or use shielded data cables in high-noise environments.

Can standard outdoor cable be used for solar panel connections?

No. Solar PV systems operate at high DC voltage and elevated temperatures. Only dedicated PV cable rated for UV exposure and 90–105°C continuous operation should be used. Standard outdoor cable degrades quickly and creates long-term safety and reliability risks.

What does ampacity actually depend on?

Ampacity depends on conductor size and material, insulation temperature rating, ambient temperature, and installation method. Cable bundling, conduit fill, and poor heat dissipation reduce allowable current. Ignoring these factors leads to overheating and premature insulation failure.

How Cable Decisions Are Made in Real Projects

In practice, factory-direct manufacturers validate cable limits under sustained load and enclosure heat, not just free-air ratings. This approach is common in ISO-certified low-voltage equipment supplied by companies like Soltree, where thermal margins and installation reality matter more than catalog numbers.

What to Remember Before You Specify or Install a Cable

Cables are engineered safety components, not interchangeable commodities. Correct selection depends on voltage class, environment, heat and load behavior, and mechanical or fire risk. The same decision logic is applied across industrial, commercial, and residential systems built around certified low-voltage products from manufacturers such as Soltree. Choose deliberately. Cable mistakes are expensive to fix later.