TLDR

Energy Management Systems deliver fast cost and risk reduction, often within 3–6 months.

Those immediate results produce measured load and power quality data that directly changes capital timing, capacity planning, and ESG credibility.

An EMS does not just inform strategy. It removes guesswork from long-term decisions.

Why Energy Management Is No Longer Just About Cost

Energy Management Systems have moved beyond tracking consumption.

What started as a cost-control tool now directly influences capital planning, asset life, sustainability reporting, and operational risk.

The shift is not philosophical. It is driven by data density and decision impact.

The core value of EMS lies in converting short-term savings into long-term decision certainty.

That certainty is what turns energy data into a strategic asset.

What You Can Fix Immediately After Deploying an EMS

Once an EMS is installed and commissioned, it starts answering operational questions that previously relied on assumptions.

Eliminate Energy Waste

-

Identify equipment running outside required schedules

-

Rank top energy consumers by actual load, not nameplate rating

-

Verify optimization impact within days, not billing cycles

Facilities typically see 5–15% consumption reduction without hardware changes, driven purely by scheduling and load visibility.

Detect Power Quality Issues Early

-

Identify harmonics above 5–8% THD before equipment derating occurs

-

Capture voltage sags that trigger PLC resets or VFD faults

-

Distinguish internal disturbances from utility-side events

Early detection often prevents transformer overheating and nuisance trips, avoiding unplanned downtime.

Reduce Safety and Reliability Risk

-

Correlate breaker trips with load and power quality events

-

Flag circuits consistently operating above 80–85% thermal capacity

-

Identify feeders approaching overload during peak production

This visibility reduces emergency shutdowns and shortens fault diagnosis time by 30–50%.

Control Demand Charges

-

Pinpoint load combinations driving monthly peaks

-

Shift or stagger loads to flatten demand curves

-

Validate results in real time

Since peak demand can account for 50–70% of commercial power bills, even small shifts produce outsized savings.

How EMS Data Drives Long-Term Decisions

Immediate savings matter.

The strategic shift happens when EMS data is accumulated and trusted.

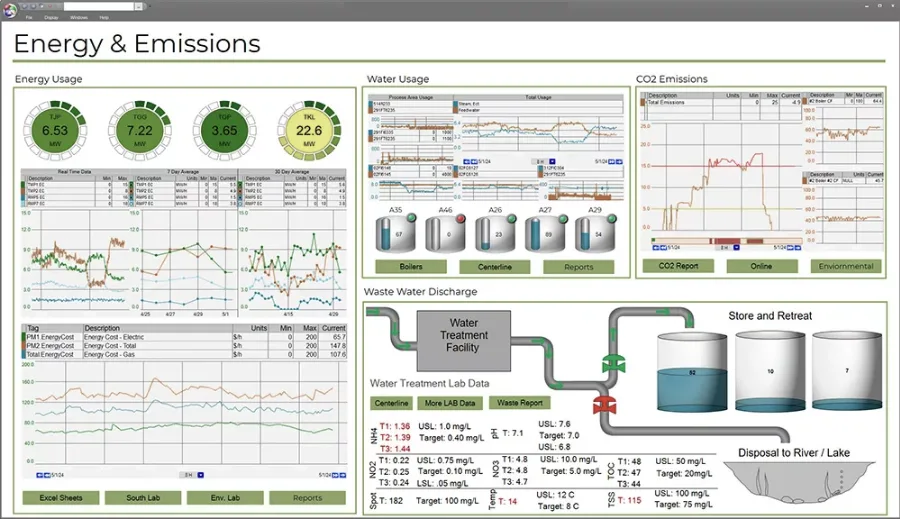

Sustainability and ESG With Audit-Grade Data

EMS replaces estimated emissions with measured values.

-

Carbon intensity is calculated from actual load profiles

-

Efficiency improvements are verified, not assumed

-

ESG reports withstand third-party audit

This avoids restatements and reduces compliance risk as reporting standards tighten.

Capacity Planning and Operational Resilience

Measured load profiles change expansion decisions.

-

Solar projects are sized to real baseload, not peak assumptions

-

EV charger deployment is limited by verified spare capacity

-

Panel and transformer upgrades are often delayed by 2–5 years

Continuous power quality monitoring also reduces catastrophic failures, shifting maintenance from reactive to predictive.

Asset and Capital Timing

EMS data alters CapEx sequencing.

-

Overbuilding of distribution capacity is reduced by 10–20%

-

Equipment replacement is triggered by condition, not age

-

Capital spend shifts from emergency to planned windows

Historical load data also sets realistic benchmarks for new facility design, avoiding inefficiency baked in from day one.

The Right Time to Deploy an EMS

Timing determines financial impact.

Greenfield Projects

Integration during design establishes a performance baseline from day one.

Meter placement and power quality visibility are optimized before construction constraints appear.

This typically reduces lifecycle energy cost by 10% or more compared to post-build retrofits.

Brownfield Facilities

If a site will operate four years or longer, delay is expensive.

-

Retrofit installations cost roughly 40% more

-

Downtime risk increases during installation

-

Energy waste continues unchecked

Measured savings during the first year often exceed the cost difference.

A Practical Deployment Path

-

Establish baseline through an energy audit

-

Define measurable operational and financial targets

-

Deploy meters and IoT sensors at decision-critical points

-

Act on load and quality findings

-

Train teams to interpret data correctly

-

Reassess quarterly and refine controls

What Actually Makes an EMS Work

Performance depends on system design, not software branding.

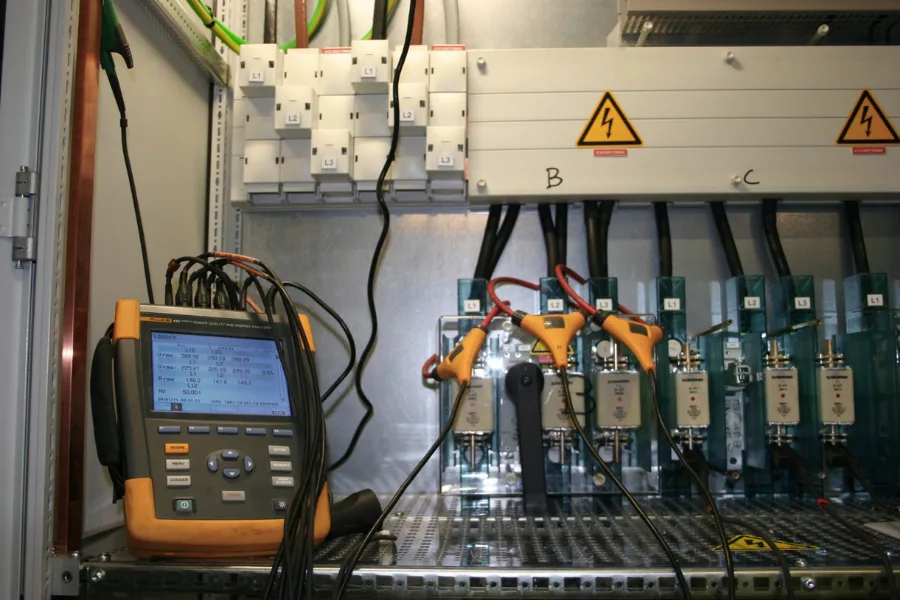

Hardware That Determines Data Quality

-

Smart meters capturing 15-minute or finer intervals

-

Sensors for temperature, humidity, occupancy, and equipment state

-

Controllers capable of executing automated responses

Meter selection rules

-

Single-circuit meters for critical or high-variance loads

-

Multi-circuit meters for panels and feeders

-

Power quality analyzers for sensitive or failure-prone systems

In low-voltage environments, teams such as Soltree typically prioritize meter placement and waveform capture accuracy before dashboard configuration, since poor data fidelity cannot be fixed in software.

Software and Connectivity

-

Analytics engines flag abnormal patterns early

-

Dashboards focus on decision clarity, not aesthetics

-

Reports support compliance and capital planning

Reliable connectivity matters.

-

Wireless mesh reduces installation disruption

-

Cellular backup maintains data continuity

-

OTA updates prevent security and compatibility drift

How EMS Differs From BAS and SCADA

Understanding boundaries avoids poor system choices.

EMS vs BAS

BAS controls HVAC, lighting, and safety systems.

Energy efficiency is a byproduct.

EMS focuses on energy intelligence.

It analyzes consumption, diagnoses power quality, predicts risk, and supports capital decisions.

EMS often ingests BAS data but delivers deeper analysis and reporting flexibility.

EMS vs SCADA

SCADA governs industrial processes and safety.

EMS optimizes energy cost and load behavior.

In industrial sites, EMS commonly layers on top of SCADA to extract energy-specific insight without disrupting production control.

How IoT and AI Expand What EMS Can Do

Technology increases precision and response speed.

-

IoT increases measurement density

-

AI predicts failure and abnormal demand

-

Autonomous controls respond to pricing and occupancy

-

Digital twins test scenarios before money is spent

This shifts EMS from monitoring to intervention.

Where EMS Delivers the Biggest Impact

If you are in one of these sectors, focus here first.

-

Manufacturing

Prioritize load profiling and predictive maintenance -

Commercial buildings

Target demand peaks and HVAC scheduling -

Data centers

Focus on cooling efficiency and power quality -

Healthcare

Balance environmental stability with energy reduction -

Cold chain and food

Optimize refrigeration cycles and compressor runtime -

Logistics and transport

Prepare infrastructure for electrification -

Utilities

Enable demand-side visibility and grid interaction

Across these environments, solution providers like Soltree consistently see the fastest ROI when EMS data is tied directly to low-voltage distribution behavior rather than aggregate billing data.

FAQ

What is the primary purpose of an EMS

An EMS acts as the energy brain of a facility. It continuously measures how energy is consumed, identifies abnormal patterns, and converts raw data into actions that reduce cost, lower operational risk, and support long-term decisions around capacity, assets, and sustainability planning.

Can EMS improve HVAC performance

Yes. An EMS improves HVAC performance by aligning operation with real occupancy, weather conditions, and system behavior. This reduces unnecessary runtime, lowers peak demand, enables predictive maintenance, and typically cuts HVAC energy use while extending equipment service life.

What is the typical ROI of an EMS

Most EMS projects achieve payback within 3–6 months. Savings come from eliminating wasted runtime, reducing peak demand charges, and avoiding emergency repairs. Facilities with high demand charges or variable loads often see faster returns due to immediate operational corrections.

When should an EMS be installed

For new facilities, EMS should be integrated during design to minimize cost and maximize data coverage. For existing sites expected to operate longer than four years, early deployment delivers higher savings and avoids the higher cost, disruption, and risk associated with later retrofits.

How does EMS differ from BAS

A BAS focuses on controlling building systems such as HVAC and lighting for comfort and safety. An EMS focuses on analyzing energy behavior across systems, identifying inefficiencies, diagnosing power quality issues, and providing data that supports cost control and long-term planning.

How does EMS support compliance and reporting

An EMS automatically collects accurate energy and emissions data, creating a reliable audit trail. This simplifies compliance with ISO 50001, ESG disclosures, and local regulations, while reducing reporting effort and improving confidence in sustainability and efficiency performance claims.

Why Early EMS Adoption Matters

Energy Management Systems are no longer optional infrastructure.

They convert volatile energy costs into controlled variables.

They turn compliance pressure into planning leverage.

Organizations that deploy EMS early delay unnecessary capital spend, reduce operational risk, and gain decision confidence before constraints force action.

The advantage compounds with every month of data collected.